Our range of services

We create concepts tailored to your requirements to increase the performance of your systems or machines. In seven steps we lead your project to the goal:

- Actual situation is assessed and recorded

- Selection of hardware components

- Creation of the schematic

- Software-Development

- Construction of hardware components

- Pre-commissioning at MSB

- Lifetime support in the field

For the development of the design we always use the latest EPLAN version and the latest TIA Portal version.

The development is done in TIA (SINAMICS Startdrive; Step7; SIMOCODE ES; SIRIUS ES; WinnCC Advanced; Safety). We offer solutions for PLC, visualization, drive technology, client servers and OPC UA. Input wizards and pre-plausibility checks are also available.

The switch cabinet production takes place in our company and is carried out by qualified specialists. Before delivery, the control cabinets are tested according to the recognized rules (e.g. ATEX, VDE, DIN, UVV). Switch cabinets up to 14 meters in length and 10 tons can be manufactured

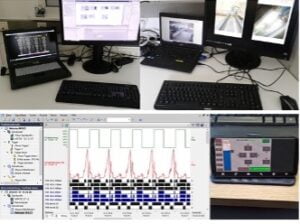

Pre-commissioning takes place in our company. The drives and processes are optimized on site. At the end of commissioning, a detailed briefing and handover takes place. We offer a lifetime and worldwide service. In addition to on-site service, we help quickly with the help of our teleservice and a client solution.

Commissioning of a control cabinet by qualified specialists

We offer lifetime and worldwide service. Besides on-site service, we help quickly with the help of our teleservice and a client solution. Thanks to a well thought-out and perfectly functioning remote maintenance, we find a fault within the shortest possible time. If a spare part is subsequently required, our technician will bring it to the agreed deployment date; unnecessary journeys to and from the site are eliminated. Our remote maintenance is rated as excellent by customers, the cost savings achieved as particularly positive.

With the BASICgrinder you „kiss“ your grinding machine awake. With this retrofit you increase the performance of your machine and have an availability of spare parts of 30 years.

MSB Schmittwerke is your partner for the construction of electrical stations for roadheaders in non firedamp protection, in CSA and also in the ATEX area. Details can be found in our flyer „Roadheader Starter 2.0 – Smart Switchgear“ under Electrics & Control.

The 11 electrical highlights of MSB Schmittwerke’s own electrical stations:

1.remote control test: The electric stations have photo-realistic visulization for testing the radio transmitter. The advantage is that troubleshooting is extremely simplified. (absolute time saving).

2. Ground fault monitoring: For the first time, the system has a ground fault system which not only switches off in the event of a fault, but also issues an early warning. Advantage: Ground faults can thus be eliminated during maintenance shifts, i.e. no machine downtime.

3. Bus-based coupling cards: MSB Schmittwerke (or former subsidiary IBS Industriemaschinen-Bergbau-Service GmbH) was the first company to use bus-based coupling cards in the mining sector. As a result, the electrical stations have this technology all over the country. The advantage of this is that faults no longer have to be measured manually, but are visualized immediately.

4. Bus-based current transformers: The advantage is that the current transformer makes it possible to visualize faults in the transformer through its „intelligent“ networking.

5. Bus systems: The MSB Schmittwerke Elektrostation communicates with 8 different BUS systems (CAN Ca; HA, CAN i; CAN B; Ethernet; Profi Bus; Profi Safe; Profi Net; Profi Net Safe; i-Profibus; DSL). This is necessary to integrate this sum of complex participants at all. Highlights are the two SIL 3 certified BUS systems. The advantage is that every point in the electrical station on the machine can be reached with a high level of safety integration. What is possible with competitors only with mechanical effort, can be achieved here by software change and simple card exchange.

6. Central software management: The software of intelligent stations is managed centrally on the CPU. The advantage is that in the event of a defect, the software automatically uploads itself to the replaced participants (no local uploading necessary). This reduces the spare parts inventory and greatly simplifies the exchange of components.

7. Two control voltages: The entire electrical station now has only two control voltages. The advantage is the low maintenance, simplicity and mainly that this greatly reduces the possibility of potential-based damage.

8. Optocouplers: Due to the widespread use of optocouplers at focal points, damage remains local.

9. Stability: Even with extremely large voltage fluctuations, the control remains active. Complete failures are thus a thing of the past. The advantage is that rebooting the control is no longer necessary (time saving).

10. Remote maintenance module: Thanks to a well thought-out and perfectly functioning remote maintenance, we find a fault within the shortest possible time. If a spare part is subsequently required, our technician brings it to the agreed deployment date; unnecessary trips to and from the site are eliminated. Customers rate our remote maintenance as excellent, and the cost savings achieved as particularly positive.

11. F-CPU and safety software tool from one portal: The electrical station has a fail-safe CPU and the software has a unified portal (safety „Normal“ program). The advantage is that everything comes from one source and not duplicated as usual.